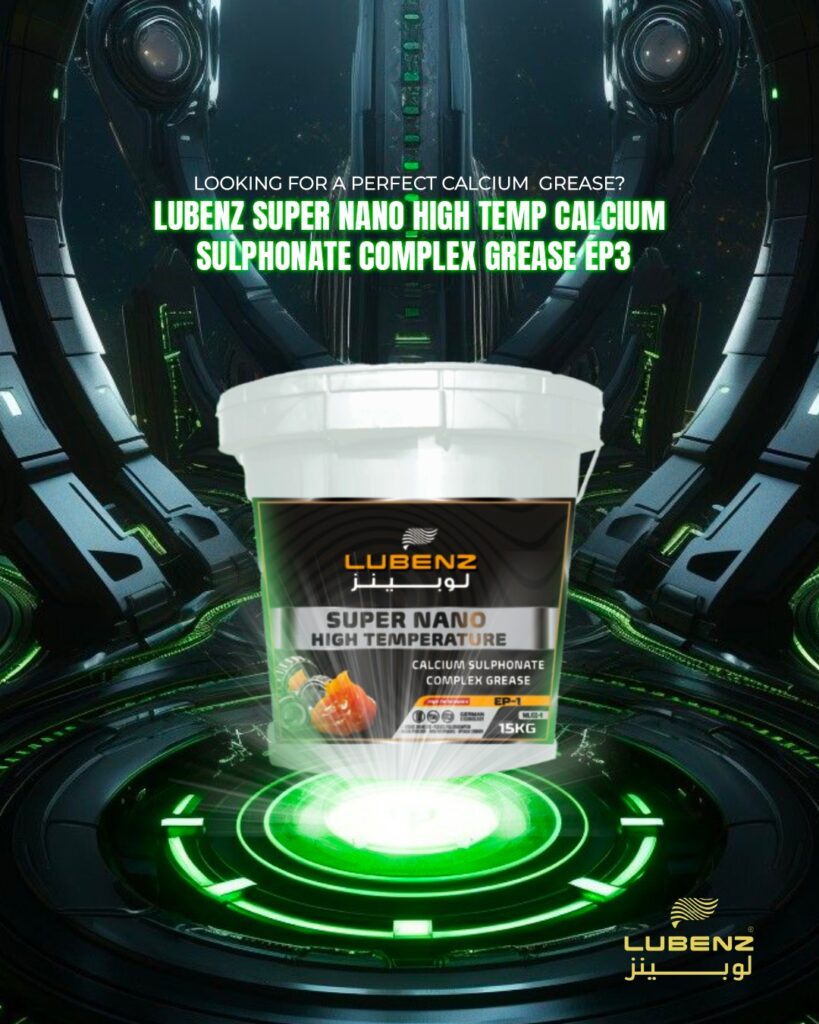

Calcium Greases wholesaler in Iraq

Calcium Greases supplier in Iraq

Calcium Greases Manufacturer in Iraq

Calcium greases are a type of lubricating grease made by thickening mineral oils or other base oils with calcium soaps, which are derived from natural fats and calcium hydroxide. These greases are known for their good water resistance, moderate temperature tolerance, and ability to protect against rust and corrosion. They are commonly used in applications where moisture or water exposure is prevalent, such as in automotive chassis components, agricultural machinery, and marine equipment. The primary function of calcium greases is to reduce friction and wear between moving parts, thereby extending the life and efficiency of the equipment.

Calcium greases possess several key features that make them effective in various industrial and mechanical applications:

Water Resistance: Calcium greases have excellent resistance to water, making them ideal for applications where exposure to moisture, humidity, or even direct water is common.

Corrosion Protection: These greases provide a protective barrier against rust and corrosion, helping to preserve the metal surfaces of machinery and equipment.

Moderate Temperature Stability: Calcium greases perform well in moderate temperature ranges, typically from -20°C to 60°C. However, they may not be suitable for very high-temperature applications.

Smooth Texture and Consistency: Calcium greases typically have a smooth and consistent texture, which allows for easy application and even distribution across surfaces.

Good Adhesion: They adhere well to surfaces, ensuring that the grease stays in place even under conditions of vibration or mechanical stress.

Oxidation Stability: Calcium greases generally exhibit good resistance to oxidation, which helps to maintain their lubricating properties over time.

Biodegradability: Some formulations of calcium greases are more environmentally friendly due to their biodegradability, making them suitable for applications where environmental impact is a concern.

Cost-Effectiveness: Calcium greases are often more affordable compared to other types of greases, offering a cost-effective solution for many standard lubrication needs.

These features make calcium greases a popular choice for lubricating machinery and equipment in various industries, especially where water resistance and corrosion protection are essential.

Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq Calcium Greases Manufacturer in Iraq

Calcium greases are widely used in various industries due to their effective lubricating properties, particularly in environments where moisture resistance is crucial. Here are some common applications:

Automotive Industry:

Used in chassis lubrication, including ball joints, steering linkages, and suspension components, where protection against moisture and road spray is essential.

Agricultural Equipment:

Ideal for tractors, plows, and other farm machinery that operates in wet or muddy conditions, providing protection against water and corrosion.

Marine Industry:

Applied to boat trailers, winches, and other equipment exposed to water, helping to prevent rust and ensure smooth operation in marine environments.

Construction Machinery:

Used in heavy-duty construction equipment like bulldozers, excavators, and cranes, particularly in components exposed to dirt, dust, and moisture.

Industrial Machinery:

Employed in general industrial applications, including bearings, gears, and other components where moderate temperature stability and water resistance are required.

Railways:

Used in the lubrication of railway components exposed to outdoor conditions, helping to prevent corrosion and ensure reliable operation.

Household Applications:

Sometimes used in door hinges, garden tools, and other household items that require light lubrication with protection against rust.

Mining Equipment:

Suitable for mining machinery, which often operates in harsh, wet conditions, providing essential lubrication and protection against wear.

Textile Machinery:

Applied in certain textile machinery components where the presence of moisture or humidity necessitates a water-resistant lubricant.

Calcium greases are chosen for these applications due to their balance of water resistance, corrosion protection, and cost-effectiveness, making them suitable for a wide range of uses in both industrial and everyday settings.

There are several myths surrounding calcium greases that can lead to misunderstandings about their properties and applications. Here are some common myths:

Myth: Calcium Greases Can't Handle Any Heat

Reality: While calcium greases are not designed for extreme high-temperature applications, they do perform well within moderate temperature ranges, typically from -20°C to 60°C. Specialized formulations can extend this range slightly, but for very high temperatures, other types of greases like lithium or complex greases are more appropriate.

Myth: All Calcium Greases Are the Same

Reality: Not all calcium greases are identical. There are different formulations, such as calcium sulfonate complex greases, which offer enhanced performance, including better heat resistance and mechanical stability compared to traditional calcium greases.

Myth: Calcium Greases Are Outdated and Obsolete

Reality: While newer types of greases have been developed, calcium greases are still widely used due to their excellent water resistance and cost-effectiveness. They remain a valuable option for many applications, particularly in environments where moisture is a concern.

Myth: Calcium Greases Are Only for Low-Load Applications

Reality: Calcium greases can handle moderate loads effectively. While they might not be the best choice for extremely high-load applications, they are suitable for many industrial and automotive uses where moderate loads are common.

Myth: Calcium Greases Are Inferior to Lithium Greases

Reality: Calcium greases and lithium greases serve different purposes and excel in different conditions. Calcium greases are superior in water resistance, making them ideal for wet environments, while lithium greases are better suited for high-temperature applications.

Myth: Calcium Greases Are Not Environmentally Friendly

Reality: Some calcium greases, particularly those formulated with biodegradable oils, are considered more environmentally friendly than other types of greases. Their simpler formulation often involves fewer additives, which can be less harmful to the environment.

Myth: Calcium Greases Require Frequent Reapplication

Reality: While it's true that calcium greases might require reapplication in certain conditions, they actually have good staying power in the right applications, particularly in wet environments where their water resistance shines.

Understanding the reality behind these myths helps in selecting the right grease for specific applications, ensuring optimal performance and equipment longevity.

Calcium greases

Calcium greases have a profoundly positive impact on various industries, particularly in environments where moisture and water exposure are significant concerns. One of the most notable benefits is their exceptional water resistance, which allows them to maintain their lubricating properties even in wet and humid conditions. This feature is crucial in industries such as agriculture, marine, and construction, where equipment is regularly exposed to harsh environmental conditions. By providing a durable lubricating film that adheres well to metal surfaces, calcium greases help prevent rust and corrosion, thereby extending the lifespan of machinery and reducing the frequency of maintenance and repairs.

In addition to their water resistance, calcium greases contribute to the overall efficiency and reliability of machinery. Their ability to reduce friction and wear between moving parts ensures smooth operation, which can lead to improved energy efficiency and reduced operational costs. This is particularly important in industries where equipment is subjected to continuous use, as it minimizes downtime and enhances productivity. The thermal stability of calcium greases, although suited for moderate temperature ranges, further supports consistent performance in varying environmental conditions, making them a versatile option for many applications.

Moreover, the cost-effectiveness of calcium greases cannot be overlooked. Their relatively simple formulation and production process make them an affordable option for many businesses, without compromising on quality. This affordability, combined with their effective performance, makes calcium greases a preferred choice for industries that require reliable lubrication solutions on a budget. Their use can lead to significant cost savings in the long term, as they reduce the need for frequent reapplication and minimize the wear and tear on expensive equipment.

Finally, the environmental aspect of calcium greases adds another layer to their positive impact. Some calcium greases are formulated with biodegradable materials, making them more environmentally friendly compared to other types of greases. This characteristic is particularly beneficial in industries where environmental regulations are stringent, and sustainability is a priority. By choosing calcium greases, companies can not only protect their machinery but also contribute to environmental conservation efforts. Overall, calcium greases play a critical role in enhancing equipment performance, reducing costs, and supporting environmental sustainability, making them an indispensable lubricant in various industrial applications.

While calcium greases offer several benefits, they also have some limitations and potential negative impacts that should be considered:

Limited High-Temperature Performance: One of the primary drawbacks of calcium greases is their limited ability to perform in high-temperature environments. They typically start to degrade at temperatures above 60°C to 80°C, which can lead to a loss of lubricating properties. In applications where temperatures regularly exceed these limits, using calcium greases can result in insufficient lubrication, increased wear, and potential equipment failure.

Lower Mechanical Stability: Compared to some other types of greases, such as lithium or complex greases, calcium greases tend to have lower mechanical stability. This means that under heavy loads or high-speed conditions, the grease may break down or become displaced from the areas where it is needed most. This can lead to inadequate protection of critical components, causing increased friction, wear, and potentially costly damage to machinery.

Oxidation and Shorter Lifespan: Calcium greases are more prone to oxidation, especially when exposed to air and high temperatures. Oxidation can lead to the formation of acidic compounds within the grease, which can corrode metal surfaces and reduce the effectiveness of the lubrication. This process shortens the lifespan of the grease, necessitating more frequent reapplication and maintenance, which can be both time-consuming and costly.

Limited Load-Bearing Capacity: Calcium greases generally have a lower load-bearing capacity compared to other greases like lithium complex or calcium sulfonate greases. In heavy-duty applications where extreme pressure is exerted on components, calcium greases may not provide adequate protection, leading to accelerated wear and potential mechanical failure. This limitation makes them unsuitable for certain high-stress industrial applications.

While calcium greases are highly effective in specific conditions, these negative impacts highlight the importance of selecting the right type of grease for each application. In environments with high temperatures, heavy loads, or where extended maintenance intervals are required, alternative greases may be more appropriate to ensure optimal equipment performance and longevity.

Calcium greases offer several key benefits that make them a popular choice for various industrial and automotive applications. Here are some of the main benefits:

Excellent Water Resistance: One of the most significant advantages of calcium greases is their ability to resist water washout. This makes them ideal for use in environments where moisture, humidity, or direct water exposure is a concern, such as in marine applications, agricultural machinery, and outdoor equipment.

Corrosion Protection: Calcium greases provide a strong protective barrier against rust and corrosion. This is especially important for equipment exposed to harsh environmental conditions, as it helps to preserve metal surfaces and extend the life of machinery.

Smooth Consistency and Easy Application: The smooth texture of calcium greases allows for easy application and ensures that the grease spreads evenly across surfaces. This consistency helps maintain effective lubrication over time, even in areas where grease needs to stay in place despite movement or vibration.

Moderate Temperature Stability: While not suitable for extreme temperatures, calcium greases perform well within moderate temperature ranges, typically from -20°C to 60°C. This makes them a reliable choice for many standard applications where extreme heat is not a factor.

Cost-Effectiveness: Calcium greases are generally more affordable compared to other types of greases, making them a cost-effective solution for many businesses. This affordability does not come at the expense of quality, as calcium greases still provide excellent performance in suitable applications.

Environmental Friendliness: Some calcium greases are formulated with biodegradable materials, making them more environmentally friendly compared to other greases. This is particularly beneficial in applications where environmental impact is a concern, such as in agriculture and other outdoor industries.

Versatility: Calcium greases are versatile and can be used in a wide range of applications, from automotive chassis lubrication to the protection of heavy industrial machinery. Their water resistance and corrosion protection make them suitable for various environments and conditions.

Good Adhesion: Calcium greases adhere well to metal surfaces, ensuring that the lubricant remains in place even under conditions of vibration or mechanical stress. This helps maintain continuous protection and reduces the need for frequent reapplication.

These benefits make calcium greases a practical and effective choice for many lubrication needs, particularly in environments where water resistance and corrosion protection are essential.

Calcium greases are known for several standout features that make them effective and widely used in various applications. Here are the key highlights:

Superior Water Resistance: Calcium greases excel in resisting water washout, making them ideal for environments where moisture or direct water exposure is common.

Effective Corrosion Protection: They provide a strong barrier against rust and corrosion, helping to extend the life of machinery and equipment exposed to harsh conditions.

Smooth Consistency: With a smooth texture, calcium greases are easy to apply and spread evenly, ensuring consistent lubrication across surfaces.

Cost-Effective: Compared to other greases, calcium greases are generally more affordable, offering reliable performance at a lower cost.

Environmental Option: Some formulations are biodegradable, making them a more environmentally friendly choice for industries concerned with sustainability.

Moderate Temperature Range: They perform well in moderate temperature ranges, typically between -20°C and 60°C, making them suitable for many standard applications.

Versatility: Calcium greases are used in a wide range of applications, from automotive to industrial machinery, thanks to their balance of water resistance and lubrication properties.

Good Adhesion: They adhere well to surfaces, maintaining lubrication even under vibration or mechanical stress, ensuring ongoing protection and performance.