Lithium grease is a versatile and widely used lubricant, known for its exceptional performance in reducing friction and wear across a broad range of applications. In the UAE, a region characterized by extreme temperatures and demanding industrial conditions, high-quality lithium grease is essential to ensure the smooth operation of machinery and equipment. Among the prominent manufacturers in this field is LUBENZ Lubricants, a trusted name in the production of premium-grade lubricants tailored to meet the unique challenges of the UAE’s industrial landscape.

Expertise in Manufacturing High-Performance Lithium Greases

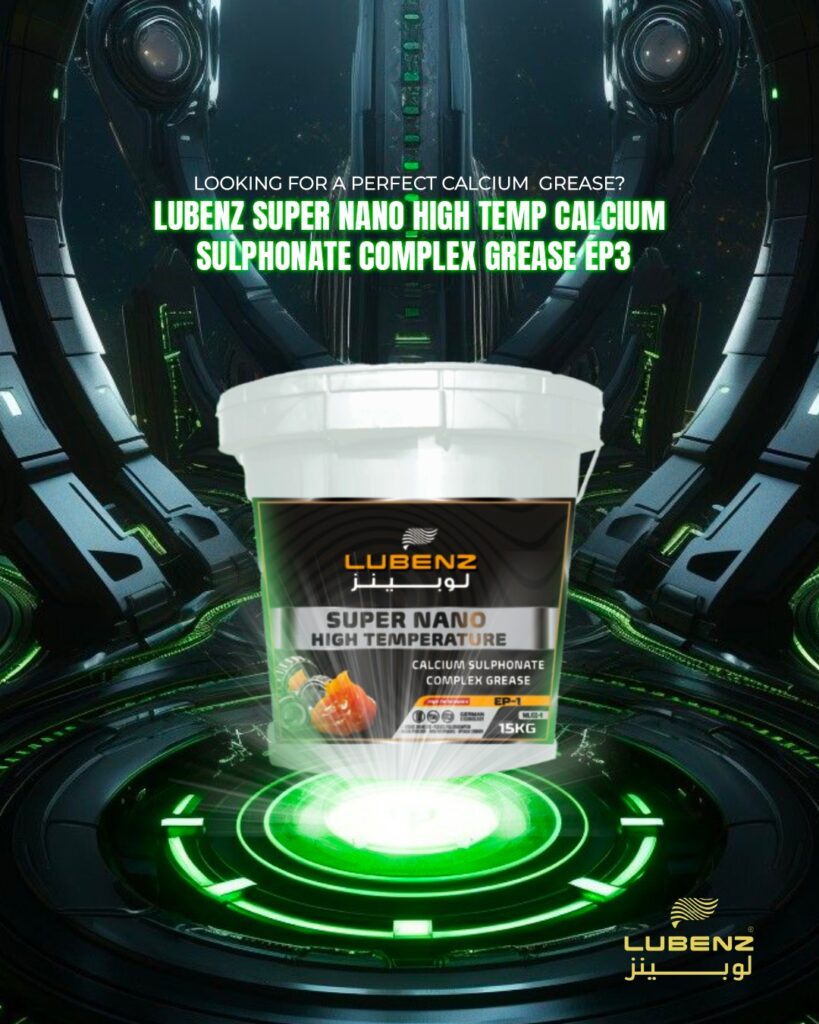

LUBENZ Lubricants stands out as a leading manufacturer of lithium greases, offering products that deliver unmatched reliability and performance. Lithium grease, a soap-based lubricant, is formulated by combining lithium soap with oils and performance-enhancing additives. Its thick, buttery consistency makes it ideal for applications requiring long-lasting lubrication and resistance to extreme pressures. LUBENZ ensures that its products meet the highest standards by employing advanced manufacturing techniques and rigorous quality control measures. The company’s greases are designed to provide excellent thermal stability, water resistance, and anti-corrosion properties, making them suitable for a wide array of applications.

Tailored Solutions for UAE’s Challenging Environment

The harsh climatic conditions of the UAE, with its scorching temperatures and occasional exposure to moisture or dust, demand specialized lubricants capable of withstanding such extremes. LUBENZ’s lithium greases are engineered to perform optimally even under these conditions. They maintain their consistency and effectiveness across a broad temperature range, ensuring that machinery remains operational and efficient. Whether used in automotive bearings, industrial machinery, or heavy construction equipment, these greases minimize downtime and enhance the lifespan of critical components.

Versatility and Applications

One of the key advantages of LUBENZ lithium greases is their versatility. They are widely used in industries such as automotive, construction, manufacturing, and marine. In automotive applications, they ensure the smooth functioning of wheel bearings, chassis components, and universal joints. In construction and heavy industries, they provide reliable lubrication for loaders, excavators, and cranes, which operate under high loads and temperatures. Additionally, their water-resistant properties make them suitable for marine environments, protecting equipment from saltwater corrosion and wear.

Commitment to Innovation and Sustainability

LUBENZ Lubricants places a strong emphasis on innovation, regularly enhancing its formulations to meet evolving industry requirements. The company incorporates eco-friendly practices in its production processes, aligning with global efforts toward sustainability. By offering lithium greases that are not only high-performing but also environmentally responsible, LUBENZ addresses the growing demand for green solutions in the UAE’s industrial sector.

Supporting Industrial Growth in the UAE

The UAE’s rapid industrialization and infrastructure development have increased the demand for reliable lubrication solutions. LUBENZ Lubricants plays a crucial role in supporting this growth by supplying lithium greases that ensure the efficient operation of critical equipment. The company’s products contribute to reducing maintenance costs, enhancing energy efficiency, and preventing equipment failures, which are vital for industries aiming to maintain high productivity levels.

As a leading manufacturer of lithium greases in the UAE, LUBENZ Lubricants combines expertise, innovation, and a deep understanding of local challenges to deliver products that exceed expectations. Their high-quality lithium greases not only enhance machinery performance but also contribute to the sustainability and efficiency of industries in the region. By addressing the unique needs of the UAE’s industrial and environmental conditions, LUBENZ continues to set benchmarks in the lubricant manufacturing sector, cementing its reputation as a trusted partner for businesses across diverse industries.