LUBRICANTS Manufacturer in Togo

Lubricants hold significant importance in Togo, influencing various sectors crucial for the country’s development and economic growth. Togo, like many developing nations, relies on a range of industries that benefit immensely from the effective use of lubricants. These sectors include transportation, agriculture, manufacturing, and energy, among others. The importance of lubricants in Togo can be understood by examining their impact on machinery performance, operational efficiency, economic benefits, and environmental sustainability.

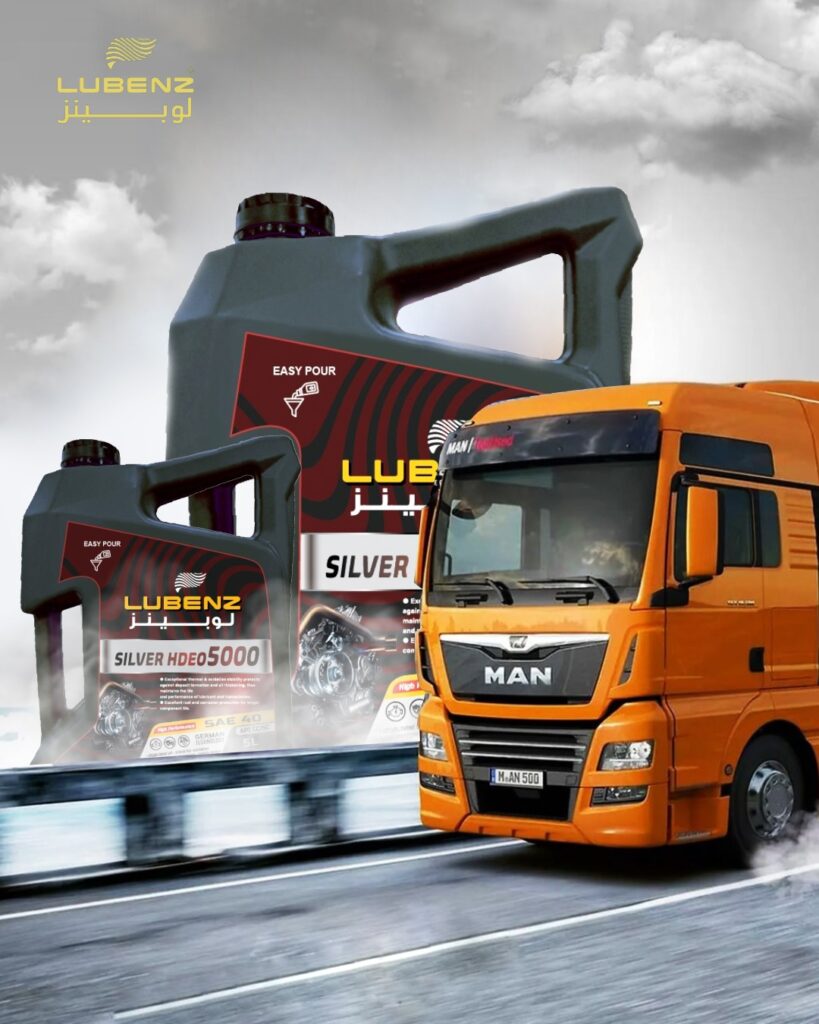

In the transportation sector, which is vital for the movement of goods and people, lubricants are indispensable. Togo’s economy relies heavily on the efficiency and reliability of its transportation network, including vehicles, trucks, and marine vessels. Proper lubrication of engines and other mechanical components reduces friction and wear, ensuring that these vehicles operate smoothly and efficiently. This not only extends the lifespan of the vehicles but also minimizes maintenance costs and downtime, which is crucial for the economic activities dependent on timely transportation. Additionally, high-quality lubricants improve fuel efficiency and reduce emissions, contributing to cost savings and environmental protection.

Agriculture, a cornerstone of Togo’s economy, also benefits significantly from the use of lubricants. Agricultural machinery, such as tractors, harvesters, and irrigation systems, must operate reliably to meet the demands of farming activities. Lubricants play a key role in maintaining these machines by preventing wear and tear, reducing breakdowns, and ensuring optimal performance during critical farming periods. This reliability is essential for enhancing agricultural productivity and supporting the livelihoods of farmers, who form a large part of Togo’s population. Efficient machinery reduces operational costs and maximizes output, directly impacting food security and economic stability.

The manufacturing sector in Togo also relies on lubricants to maintain the performance and efficiency of industrial machinery. Factories and production plants utilize a wide range of equipment that must function seamlessly to meet production targets and quality standards. Lubricants help in reducing friction, dissipating heat, and protecting against corrosion, all of which are critical for the uninterrupted operation of machinery. By preventing premature wear and extending the lifespan of equipment, lubricants contribute to reducing operational costs and improving overall productivity. This, in turn, enhances the competitiveness of Togolese products in both local and international markets.

Furthermore, the energy sector, including power generation and mining, depends on lubricants for the smooth operation of heavy machinery and equipment. Power plants and mining operations involve complex machinery that operates under high stress and harsh conditions. Effective lubrication ensures that these machines run efficiently, reducing the risk of costly breakdowns and ensuring a steady supply of energy and minerals. This reliability is essential for sustaining industrial activities and supporting the broader economic development of Togo.

In addition to these direct benefits, the proper use of lubricants in Togo has broader economic implications. The lubricants industry itself creates jobs and stimulates economic activity through the production, distribution, and retail of lubricants. Moreover, the use of high-quality, efficient lubricants can attract foreign investment by showcasing a commitment to maintaining and optimizing industrial operations. This investment can lead to technological advancements and improved infrastructure, further boosting economic growth.

Environmental sustainability is another critical aspect of the importance of lubricants in Togo. The use of environmentally friendly lubricants and proper waste management practices help mitigate the environmental impact of industrial activities. Biodegradable lubricants and efficient recycling programs can prevent soil and water contamination, contributing to the protection of Togo’s natural resources. This is particularly important in a country where agriculture and natural resources play a significant role in the economy.

In conclusion, lubricants are of paramount importance in Togo, supporting key sectors such as transportation, agriculture, manufacturing, and energy. They enhance machinery performance, improve operational efficiency, reduce costs, and contribute to economic growth and environmental sustainability. The strategic use and management of lubricants are essential for Togo’s continued development and prosperity.

Lubricants offer a multitude of benefits in Togo, significantly impacting various sectors and contributing to the country’s economic and environmental well-being. These benefits are critical in enhancing machinery performance, reducing operational costs, ensuring sustainability, and supporting the overall development of the nation.

Enhanced Machinery Performance and Longevity

In Togo, lubricants are essential for improving the performance and extending the lifespan of machinery across different sectors. In the transportation industry, high-quality lubricants reduce friction and wear in engines, ensuring vehicles such as cars, trucks, and marine vessels operate smoothly and efficiently. This leads to fewer breakdowns and less frequent maintenance, which is particularly crucial for the reliable transportation of goods and people. Similarly, in agriculture, lubricants maintain the efficiency of tractors, harvesters, and irrigation systems, ensuring uninterrupted farming operations and enhancing productivity.

Economic Efficiency and Cost Savings

The use of lubricants in Togo’s industrial and agricultural sectors results in significant cost savings. By reducing wear and tear on machinery, lubricants decrease the need for repairs and replacements, lowering maintenance costs. This is especially important for small and medium-sized enterprises that may operate on tight budgets. In the manufacturing sector, the use of effective lubricants ensures that production lines run smoothly, minimizing downtime and maximizing output. This efficiency translates into higher profitability and competitive advantage for Togolese manufacturers, both locally and in international markets.

Energy Efficiency and Environmental Protection

Lubricants play a crucial role in improving fuel efficiency, which is beneficial for both economic and environmental reasons. In the transportation sector, the use of advanced lubricants reduces fuel consumption, lowering operational costs and reducing greenhouse gas emissions. This contributes to a cleaner environment and aligns with global efforts to combat climate change. Moreover, environmentally friendly lubricants, such as biodegradable oils, help protect Togo’s natural resources by preventing soil and water contamination. Proper waste management and recycling programs for used lubricants further enhance environmental sustainability.

Support for Key Economic Sectors

Lubricants are vital for the smooth operation of key economic sectors in Togo, such as energy and mining. In the energy sector, lubricants ensure the reliable performance of power generation equipment, which is essential for maintaining a stable supply of electricity. This reliability supports industrial activities and economic growth. In mining, lubricants protect heavy machinery from harsh operating conditions, reducing the risk of costly breakdowns and ensuring continuous extraction of minerals. These sectors are pivotal for Togo’s economic development, providing employment opportunities and contributing to the country’s GDP.

Job Creation and Technological Advancements

The lubricants industry itself creates jobs in production, distribution, and retail. This stimulates economic activity and provides employment opportunities for Togolese citizens. Additionally, the demand for high-quality lubricants can attract foreign investment and partnerships, leading to the introduction of advanced technologies and best practices in the industry. This influx of expertise and capital can further enhance the efficiency and competitiveness of Togolese businesses, fostering innovation and growth.

Improved Safety and Operational Reliability

Lubricants contribute to the safety and reliability of machinery and equipment. In industrial settings, properly lubricated machines are less likely to overheat, fail, or cause accidents, ensuring a safer working environment for employees. This is particularly important in sectors such as manufacturing and mining, where equipment failure can have serious safety implications. Regular maintenance and the use of high-quality lubricants help prevent such risks, promoting a culture of safety and reliability.

In conclusion, the benefits of lubricants in Togo are far-reaching, impacting machinery performance, economic efficiency, environmental sustainability, and safety across various sectors. By enhancing the reliability and efficiency of transportation, agriculture, manufacturing, and energy industries, lubricants play a pivotal role in supporting Togo’s economic development and environmental protection efforts. Their strategic use and management are essential for ensuring the country’s continued growth and prosperity.